🧵 The Ultimate Guide to Woven Geotextile Fabric for Soil Stabilization

“Woven vs Non-Woven Geotextile: Discover the Best Fabric!”

“Woven vs Non-Woven Geotextile: Discover the Best Fabric!”

Introduction

Woven geotextile fabric is a high-performance geosynthetic material widely used in civil engineering, environmental protection, and construction. This comprehensive guide delves into its features, benefits, practical uses, and installation tips. Whether you’re an engineer, contractor, or supplier, this guide will help you understand the full value of woven geotextile fabric.

What Is Woven Geotextile Fabric?

Woven geotextile fabric is manufactured by weaving two sets of synthetic yarns—typically polypropylene or polyester—into a durable, stable fabric. It offers high tensile strength and minimal elongation, making it ideal for soil reinforcement, separation, and stabilization.

🔍 Key Features and Specifications of Woven Geotextile Fabric

High Tensile Strength: Ranges from 20 to 200 kN/m, suitable for heavy-duty applications.

Low Elongation: Maintains shape and support under pressure.

Effective Filtration: Allows water flow while retaining soil particles.

UV and Chemical Resistance: Long-lasting under harsh environmental conditions.

Flexible Sizes: Available in rolls from 1 to 6 meters wide.

📌 Common Applications of Woven Geotextile Fabric

🚧 Road Construction and Pavement Reinforcement

Woven geotextile fabric is laid beneath roads and highways to enhance load-bearing capacity and prevent rutting. As a result, it extends pavement life while reducing maintenance frequency.

🚄 Railway and Airport Infrastructure

In rail and airport projects, the fabric improves the performance of weak subgrades. It reinforces the base and ensures long-term structural integrity.

🧱 Retaining Walls and Embankments

The fabric serves as a barrier between different soil layers, preventing mixing and ensuring a stable foundation for retaining walls and embankments.

🗑️ Landfills and Containment Systems

Woven geotextile fabric acts as a containment layer that supports landfill linings, helping to isolate hazardous waste from the surrounding environment.

🌊 Erosion Control Along Riverbanks and Slopes

The fabric prevents soil loss while allowing natural drainage. Therefore, it is a popular choice for coastal and slope protection projects.

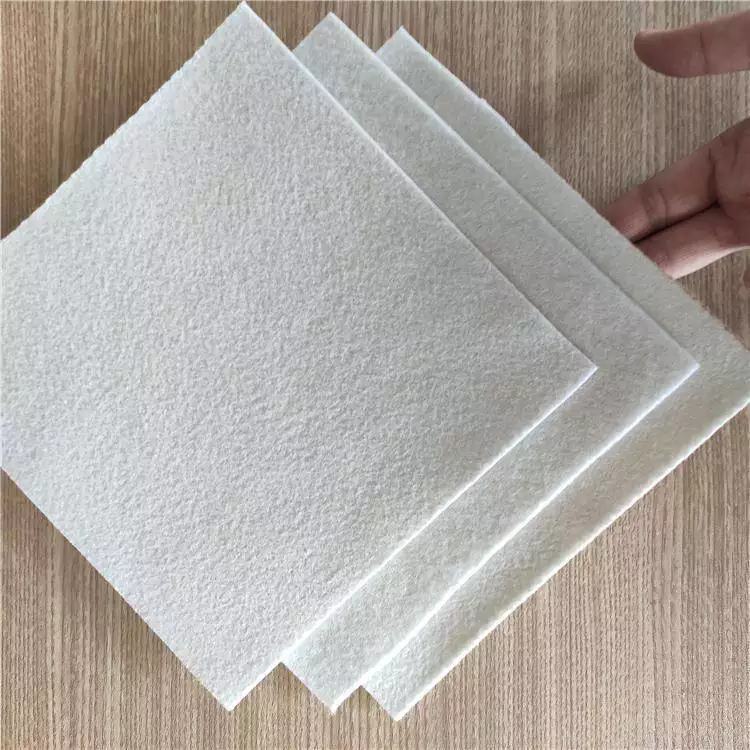

🔄 Comparison with Nonwoven Geotextile Fabric

While both woven and nonwoven geotextiles are used in geotechnical applications, their properties differ significantly:

| Property | Woven Geotextile | Nonwoven Geotextile |

|---|---|---|

| Tensile Strength | High | Moderate |

| Filtration | Moderate | High |

| Drainage | Moderate | High |

| Cost | Lower | Slightly Higher |

👉 Tip: Choose woven geotextile for reinforcement, and nonwoven for filtration or drainage-dominated applications.

🛠️ Installation Guidelines for Woven Geotextile Fabric

Step 1: Site Preparation

Clear the surface of debris, vegetation, and sharp objects to prevent damage during installation.

Step 2: Fabric Placement

Unroll the geotextile fabric in the direction of the work. Overlap joints by at least 30 cm (12 inches) to ensure continuous coverage.

Step 3: Anchoring the Fabric

Use staples, pins, or soil weights to secure the fabric before covering it with aggregate or backfill.

Step 4: Quality Inspection

Check for tears, misalignments, or insufficient overlaps. Consistent tension should be maintained across the fabric.

🧪 Case Study: Road Stabilization Project in Texas

A large-scale road project in Texas involved soft subgrade conditions that threatened long-term road integrity. By incorporating woven geotextile fabric beneath the base layer, engineers reduced aggregate use by 30% and extended the road’s life span by over 50%. This application significantly lowered both installation and maintenance costs.

🌟 Advantages of Woven Geotextile Fabric

Improved Load-Bearing Capacity

Extended Lifespan of Infrastructure

Reduced Long-Term Maintenance

Increased Site Safety and Stability

Sustainable and Recyclable Material

🔗 Internal and External Resources

🧾 Conclusion

Woven geotextile fabric is an essential tool in modern civil engineering and environmental protection. Its ability to reinforce, stabilize, and separate soil layers makes it indispensable for roadways, railways, retaining structures, and erosion control. By selecting the appropriate fabric type and following correct installation practices, construction professionals can ensure safer, more durable, and cost-effective infrastructure.

📬 For pricing, product specifications, or custom inquiries, visit Jingze Geo.com