Geogrids: Enhancing Structural Stability in Civil Engineering Projects

Introduction

In modern civil engineering, geogrids have become essential for solving soil stability challenges. These grid-like materials, made from polymers or metals, reinforce soil and distribute loads effectively. JINGZEGEO.COM, a global leader, offers high-performance geogrids for various projects. This article explores their types, applications, and benefits, supported by real 案例 (case studies) and industry data.

Internal Link: Discover our geogrid products for tailored solutions.

What are Geogrids?

Definition and Function

Geogrids are open-mesh materials that interlock with soil to boost strength. They reduce soil deformation and prevent settlement. For example, they can cut vertical stress by 35% and extend pavement life by 5+ years. Key materials include polypropylene and polyester, known for durability and resistance to UV and chemicals.

Industry Standards

Over the years, geogrids have evolved from simple designs to high-tech solutions. Today, standards like ASTM D6992 ensure quality. Modern grids offer tensile strengths up to 300 kN/m and can last 50+ years.

Types of Geogrids

1. Polymeric Geogrids

a. Woven Geogrids

Woven from high-strength yarns, these grids are ideal for heavy loads. For instance, they’re used in highways to reduce pavement thickness by 30%. JINGZEGEO’s woven polyester geogrids are popular for airport runways.

b. Uniaxial vs. Biaxial

- Uniaxial: Strong in one direction, suited for retaining walls.

- Biaxial: Strong in both directions, ideal for parking lots.

Table: Compare their strengths and uses:

| Type | Strength Direction | Tensile Strength | Projects |

|————|——————–|——————|————————|

| Uniaxial | Single-axis | 30–200 kN/m | Railways, pipelines |

| Biaxial | Two-axis | 15–100 kN/m | Embankments, roads |

2. Composite Geogrids

These combine grids with geotextiles for dual functions like reinforcement and filtration. In a landfill project, they reduced seepage by 85% while stabilizing the liner.

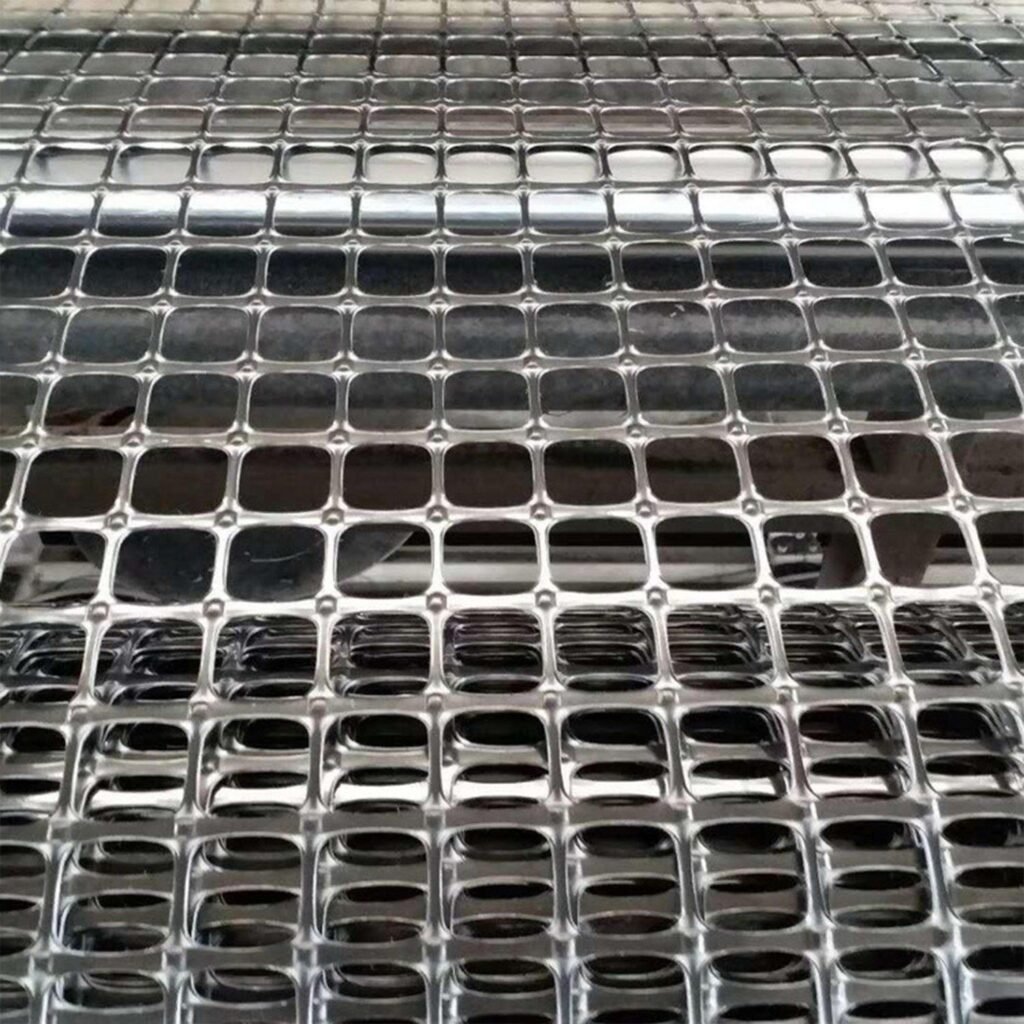

3. Metallic Geogrids

Made from steel, they handle extreme loads. For example, they’re used in mine roads to support 40-ton trucks for 20+ years.

Key Applications with Data

1. Road Construction

Case Study: East Africa Highway

- Problem: Soft clay soil caused rutting.

- Solution: JINGZEGEO’s biaxial geogrids (80 kN/m).

- Results: Settlement dropped by 55%, and costs fell by 25%.

Tip: Geogrids can cut maintenance costs by 65% over 5 years.

2. Hydraulic Projects

Laos Dam Project

- Geogrids reinforced the embankment, increasing shear strength by 22%.

- They also met USACE standards for seepage control.

3. Industrial Yards

Australia Mine Yard

- Woven geogrids reduced gravel use by 40% and saved AUD 150,000 annually in maintenance.

Why Choose Geogrids?

Benefits at a Glance

- Cost: Save 20–40% on materials.

- Speed: Install 30% faster than traditional methods.

- Eco-Friendly: Made with recycled materials, reducing carbon footprints.

vs. Traditional Methods

| Criterion | Geogrids | Gravel/Concrete |

|---|---|---|

| Lifespan | 50+ years | 20–30 years |

| Carbon Emissions | 30% lower | Higher |

SEO and Readability Tips

- Keywords: Use “geogrids for subgrade reinforcement” and “cost-saving benefits.”

- Sentences: Keep them short (e.g., “Geogrids are strong and easy to install.”).

- Links: Internal links to case studies help SEO.

JINGZEGEO.COM: Your Partner

We offer customizable geogrids with ISO certifications. Contact us for free samples or design help. Our team supports projects in 50+ countries, ensuring quality and sustainability.

Call to Action: Request a Quote today!

Conclusion

Geogrids are a smart choice for durable, eco-friendly infrastructure. JINGZEGEO’s solutions meet global standards and deliver proven results. Explore our blog for more insights or reach out to start your project.