Non Woven Geotextile FabricGeotextiles are a vital component in modern construction, drainage systems, and erosion control projects. If you’re looking to make your project more durable, efficient, and cost-effective, choosing the right type of geotextile fabric is essential. In the world of geosynthetics, two major types of fabric come into play: woven geotextile fabric and non-woven geotextile fabric.

While these fabrics serve similar purposes, they each have distinct features, applications, and benefits. In this article, we will dive into the key differences, applications, and advantages of woven geotextiles and non-woven geotextiles. By the end, you will have a clear understanding of which fabric will best suit your needs and project goals.

What is Geotextile Fabric?

Geotextile fabrics are synthetic materials made from polypropylene (PP) or polyester (PET), commonly used in civil engineering, construction, and landscaping projects. They enhance soil performance by performing multiple functions, including separation, filtration, drainage, reinforcement, and protection.

Geotextiles are a type of geosynthetic material that can be integrated with other geosynthetics, such as geomembranes, geogrids, and geocomposites. They are commonly used for road construction, erosion control, drainage, and environmental protection projects.

What is Woven Geotextile Fabric?

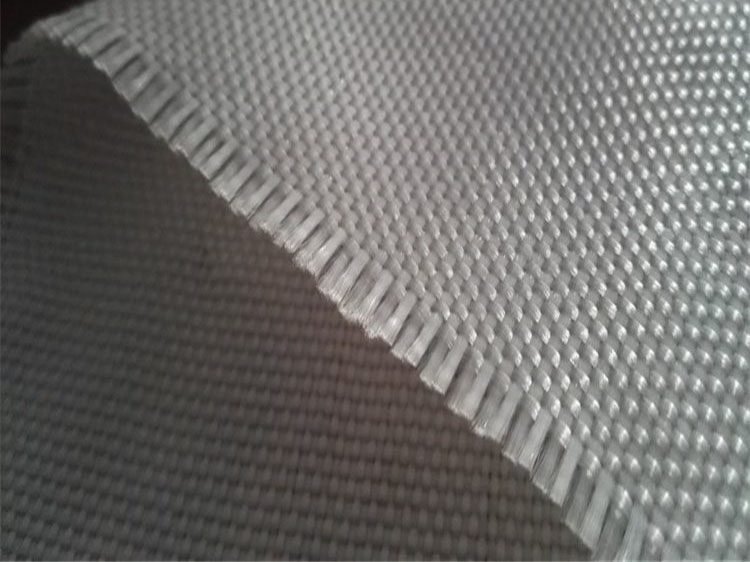

Woven geotextile fabrics are produced by weaving synthetic yarns together in a grid-like pattern. This intricate interlacing results in fabrics with high tensile strength, stability, and durability. Woven fabrics offer the ability to withstand heavy loads and resist deformation, making them ideal for load-bearing applications.

Key Characteristics of Woven Geotextile Fabrics:

- High Tensile Strength: Woven fabrics are perfect for projects requiring strength and structural integrity, such as road construction and retaining walls.

- Low Elongation: Due to their low elongation, woven fabrics maintain their shape even under extreme pressure and stress.

- Moderate Permeability: Although woven geotextiles allow some water flow, they are not as permeable as non-woven geotextiles, which means they are not ideal for high-drainage applications.

Applications of Woven Geotextile Fabrics:

- Road and Highway Construction: Woven geotextiles are used in road stabilization, subgrade reinforcement, and base course support to improve the strength and durability of road structures.

- Retaining Wall Systems: These fabrics help in soil separation and erosion control, stabilizing the backfill material behind retaining walls.

- Railroad Track Construction: Used under tracks to reinforce the soil and prevent deformation.

Advantages of Woven Geotextile Fabrics:

- High tensile strength for load-bearing applications

- Long lifespan with UV and chemical resistance

- Efficient soil separation and reinforcement properties

- Cost-effective in heavy-duty applications

Disadvantages of Woven Geotextile Fabrics:

- Limited filtration and drainage capabilities

- Not suitable for erosion control or water flow applications

What is Non-Woven Geotextile Fabric?

Non-woven geotextile fabrics are created by bonding fibers together using needle-punching or thermal fusion processes. These fabrics are flexible, soft, and have high permeability, making them ideal for applications where water flow and filtration are critical.

Non-woven geotextiles are manufactured using polypropylene, polyester, or polyethylene, and they are often used in projects where drainage, erosion control, and soil filtration are primary concerns.

Key Characteristics of Non-Woven Geotextile Fabrics:

- High Permeability: These fabrics allow for easy water passage and filtration, making them ideal for drainage systems and landfill liners.

- Excellent Filtration: Non-woven geotextiles are highly effective at preventing soil particles from clogging drainage systems, making them suitable for filtration applications.

- Flexible and Adaptable: Due to their soft nature, non-woven geotextiles can easily conform to irregular surfaces, offering a more versatile solution for various projects.

Applications of Non-Woven Geotextile Fabrics:

- Drainage Systems: These fabrics are used to enhance water flow and prevent soil clogging in drainage systems, including drainage trenches, landfills, and stormwater management systems.

- Landfill Liners: Non-woven geotextiles help in separating hazardous materials from the soil, reducing the risk of contamination in landfills.

- Erosion Control: Used in areas prone to soil erosion, these fabrics stabilize the soil and reduce water runoff.

Advantages of Non-Woven Geotextile Fabrics:

- High permeability and water flow for drainage applications

- Excellent filtration and soil separation properties

- Cost-effective and flexible for various soil conditions

- Ideal for erosion control, landfill liners, and drainage systems

Disadvantages of Non-Woven Geotextile Fabrics:

- Lower tensile strength compared to woven fabrics

- Not ideal for heavy-duty load-bearing applications

Comparison of Woven and Non-Woven Geotextiles

To summarize the differences between woven and non-woven geotextiles, here is a comparison table:

| Feature | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Manufacturing | Woven from yarns | Needle-punched or thermally bonded fibers |

| Tensile Strength | High | Medium to High |

| Elongation | Low | High |

| Permeability | Low | High |

| Filtration | Moderate | Excellent |

| Soil Separation | Excellent | Good |

| Drainage | Moderate | Excellent |

| Appearance | Grid-like | Felt-like |

When to Choose Woven Geotextiles

Choose woven geotextiles if your project requires high strength, load-bearing capacity, and soil separation. These fabrics are ideal for heavy-duty applications like road construction, railroad tracks, and retaining walls. Their ability to withstand stress and provide reinforcement makes them the perfect solution for load-bearing structures.

When to Choose Non-Woven Geotextiles

Non-woven geotextiles are best suited for projects that require high drainage, filtration, and erosion control. If you’re working on drainage systems, landfill liners, or erosion-prone areas, non-woven geotextiles provide the perfect balance of flexibility, permeability, and cost-effectiveness.

Durability and Environmental Resistance

Both woven and non-woven geotextiles are designed to endure tough environmental conditions, including UV exposure, chemical degradation, and physical stress. However, woven geotextiles tend to have a longer lifespan in applications involving high tensile strength.

Cost Comparison

The cost of geotextiles varies depending on material, thickness, and intended use. While woven geotextiles tend to be more expensive, their strength and durability make them suitable for heavy-duty projects. Non-woven geotextiles, on the other hand, offer a more cost-effective solution for drainage and filtration applications.

| Type | Approximate Cost (USD/sqm) | Lifespan |

|---|---|---|

| Woven | $0.20 – $0.60 | 30–50 years |

| Non-Woven | $0.30 – $0.90 | 25–40 years |

Conclusion

Both woven geotextiles and non-woven geotextiles offer distinct advantages depending on your project needs. Woven fabrics excel in load-bearing applications and reinforcement, while non-woven fabrics are ideal for drainage, filtration, and erosion control. By understanding the key differences between these two types of geotextiles, you can make an informed decision and ensure the success of your project.

Contact Jingze Geosynthetics for Expert Support

At Jingze Geosynthetics, we offer a wide range of high-quality woven and non-woven geotextile fabrics. Our products are designed for durability, performance, and environmental sustainability. If you’re looking for geotextile fabric suppliers, contact us today for a free sample and expert advice.

For more information on our geotextile products, visit our Geotextile Fabric page.